With one year in the rearview mirror, FirstBuild takes lessons learned as GE’s first startup, global online co-creation community and microfactory to plan for what is shaping up to be an even more exciting second year.

FirstBuild is GE’s “co-creation community.” Described as a physical and online community dedicated to conceiving, designing, engineering and building the next generation of major home appliances. It fosters co-creation among engineers, designers, makers and home enthusiasts worldwide by enabling them to participate in the development of appliances to ensure FirstBuild brings products to market people actually want.

FirstBuild is GE’s “co-creation community.” Described as a physical and online community dedicated to conceiving, designing, engineering and building the next generation of major home appliances. It fosters co-creation among engineers, designers, makers and home enthusiasts worldwide by enabling them to participate in the development of appliances to ensure FirstBuild brings products to market people actually want.

Earlier this year, FirstBuild launched the Paragon Induction Cooktop earlier this week with discount pricing through a crowdfunding campaign on Indiegogo. Paragon enables home cooks to achieve restaurant quality results for a variety of cooking techniques using a Bluetooth-connected temperature sensor and associated iOS app. The 1,400-watt Paragon Induction Cooktop controls temperatures within 1 degree Fahrenheit so it can be used for precision cooking techniques like sous vide.

Other achievements include:

Global online co-creation community members—over 7,500—from all over the world worked together to create the next great thing in appliances. Products like the Paragon™ Induction Cooktop, ChillHub™ Refrigerator and Opal™ Nugget Ice Maker resulted from this innovative collaboration.

Global online co-creation community members—over 7,500—from all over the world worked together to create the next great thing in appliances. Products like the Paragon™ Induction Cooktop, ChillHub™ Refrigerator and Opal™ Nugget Ice Maker resulted from this innovative collaboration.

- Microfactory in Louisville started producing microkitchens and the Easy-Load Double Ovens, among other products, in small batch production. Products that start at FirstBuild can scale up to large-scale production in GE’s factories across the country. This new model reduces the cost and risk of product development and enables fast market validation, so products make it to market faster.

- University of Louisville (UofL) students working with FirstBuild on 32 capstone projects—giving them access to state-of-the-art manufacturing equipment and real–life experiences unavailable in a classroom setting and facilitated well over 100 personal projects created by local makers, startups and entrepreneurs—developing a new model of successful public/private partnerships. The microfactory site in UofL’s Belknap campus saw over 3,000 people visiting or working in its lab spaces.

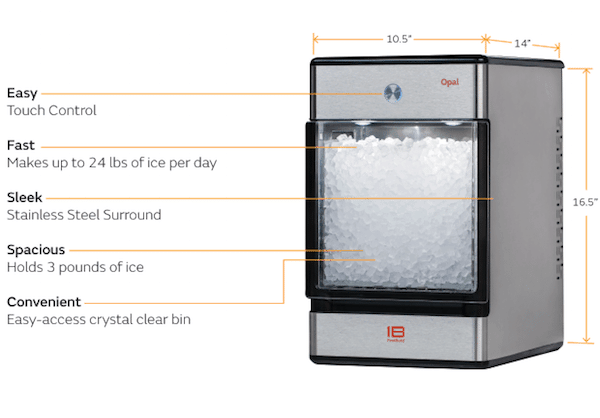

FirstBuild has also returned to Indiegogo with a new project, the Opal Nugget Ice Maker. Originally seeking $150,000, the company surpassed its initial goal and secured nearly $500,000 during the first 24 hours of its campaign.

FirstBuild has also returned to Indiegogo with a new project, the Opal Nugget Ice Maker. Originally seeking $150,000, the company surpassed its initial goal and secured nearly $500,000 during the first 24 hours of its campaign.

Opal is described as an ice maker designed for the enthusiasts: people who drop by their favorite restaurant on the weekend to pick up a bag of that special soft ice or have googled “nugget ice maker for home” only to find that home nugget ice makers start at $2000 – $3000. The company shared:

“Opal nugget ice is made by scraping the ice flakes off the inside of a chilled aluminum cylinder. The flakes are extruded through a round hole, compacting them into frozen nuggets of air and ice. Nugget ice is about 50% air by volume, and those tiny pinholes of air between the ice flakes are the secret to soft, chewable, flavorful ice.”

Features are the following:

The new campaign is set to close in late August.

____________________________________________

Have a crowdfunding offering you'd like to share? Submit an offering for consideration using our Submit a Tip form and we may share it on our site!